United Abrasives/SAIT Creates New High-Performance Ceramic Products

May 18th 2021

Over the past year, United Abrasives/SAIT has been busy bringing new products to market to meet the changing needs of its customers.

UA/SAIT created a line of 9” portable saw blades for use with popular battery-powered cordless cutoff saws, and a new line of ceramic-coated flap discs and grinding wheels, all of which are made in the USA.

9” Portable Saw Blades

In response to the growing interest in 9" battery powered cordless cut-off saws, UA/SAIT developed a line of 9" portable saw blades specifically made for these tools. The blades are available in two formulas (A60S General Purpose and Ultimate Ceramic Cut-Off™ Premium Performance) for a variety of applications. The line of premium performance cut-off blades is designed to maximize the performance and battery life of the new cordless portable saws.

Both types of blade come in a Type 1/Type 41 shape for square, burr-free cutting, and they are made of the highest quality fiberglass to withstand the toughest applications. Both are for use with ferrous and non-ferrous metals (iron, steel, stud, rebar, etc.) and The Ultimate Ceramic Cut-Off™ also may be used with stainless steel and high-tensile alloys.

Other features specific to each formula include:

- General Purpose

- Special aluminum oxide grain

- Exceptional performance and extremely fast burr-free cutting with long life

- Premium Performance

- Premium ceramic aluminum oxide grain

- Exceptionally long-lasting design that maximizes productivity for fewer wheel changes

Ceramic-Coated Discs and Wheels

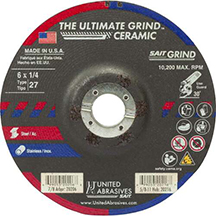

Increasing interest in products made from high-end ceramic grains led UA/SAIT to develop a variety of premium performance ceramic items ranging from the 7-11 and 9-11 ceramic fiber discs to The Ultimate Grind™ Ceramicgrinding wheel.

All these new ceramic products were developed with the end user in mind, and vigorous testing was done to ensure that these products can handle the toughest applications while increasing productivity.

Here’s a look at the features of each of these new ceramic products:

- Highest performing disc for carbon steel

- High density ceramic grain for maximum performance

- Application: blending and grinding

- For use with carbon steel and cast iron

- Highest performing disc for stainless and high alloyed steels

- High density ceramic grain for max performance with grinding aids for reduced heat and decreased loading

- Application: blending and grinding

- For use with stainless steel, high tensile alloys, carbon steel, cast iron, and non-ferrous metals (aluminum, copper, brass, etc.)

- Extremely fast grinding

- Best choice for maximum stock removal

- Premium high-ratio ceramic grain for increased efficiency and performance

- Type 27

- Highest quality ceramic aluminum oxide grain for tough applications

- All sizes are made with uniform grain throughout, no filler grain used

- All wheels are internally reinforced with the highest quality fiberglass for maximum safety

- Application: grinding

- For use with ferrous metals (iron, steel, welds, etc.), stainless steel, and high tensile alloys