Ultimate Comfort and Safety with Miller Supplied Air Respirator System

Jun 4th 2020

- OSHA classification of a loose-fitting supplied air respirator (no fit test required).

- Assigned Protection Factor (APF) of 25.

- Certifications include NIOSH 42 CFR 84 (SAR system) and ANSI Z87.1+ 2015 (helmet).

- Lightweight and versatile, the C50 Air Regulator can be positioned horizontally or vertically to naturally align with body movement.

- The C50 Air Regulator provides Grade D breathing air as cool as 50 degrees Fahrenheit (28°C) under the helmet, heightening productivity and relieving heat stress.

- Adjustable interior vents allow for customized air flow depending on user preference.

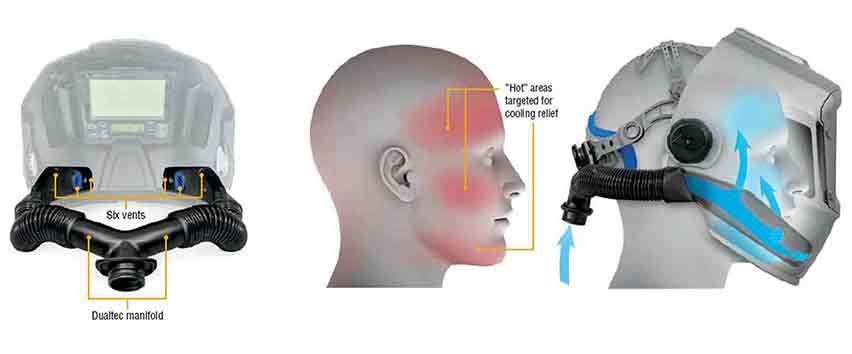

- Dualtec™ Manifold System with 6-point airflow distribution system maximizes perceived cooling by targeting “hot” areas within the face for immediate cooling relief, without causing eye or nose irritation.

- Flame-resistant, washable head seal with ultra-soft outer cuff enhances wear without causing skin irritation. This unique design can provide additional protection by covering the ears, or ease communication if placed in front of the ears. The cape offers necessary head protection in out-of-position applications.

- Integrated shoulder straps provide a secure fit and equally distribute weight, alleviating lower back strain.

- ClearLight™ lens technology optimizes contrast and clarity in welding and light states, while providing a brighter light state to increase helmet-on time for non-welding tasks, enhancing visibility and reducing eye strain.

- Shade 5.0 side windows and oversized clear grind shield maximize downward and peripheral visibility. The industry's largest grind shield provides 44 square inches of clear viewing area for grinding and other tasks, which increases helmet on time and decreases the potential for eye injuries.

- Half-shade lens adjustability provides fine shade adjustment for optimized comfort and vision.

- The helmet’s well-balanced design reduces neck torque, which minimizes operator fatigue and strain leading to an increase in comfort as well as long-term health benefits.

- Ergonomic headgear provides a secure fit, while avoiding major pressure points on the head to maximize all-day wear. The fit is completely customizable with tilt, distance and tightness adjustments.

- Four lens operating modes: weld, cut, grind and X-Mode, which senses the arc’s electromagnetic field rather than arc rays to darken the lens and is ideal for outdoor low-amp TIG and obstructed-view applications. Infotrack™ 2.0 allows for monitoring of arc time and arc count. Simplistic digital lens interface allows for easy adjustment with or without gloves.

- First stage removes 95 percent of liquids and particulate down to 5.0 microns.

- Second stage removes 99.99 percent of fine oil mists and particulate down to .01 microns in size.

- Third stage removes organic vapors, odors and tastes.

- Filters provide protection from Hexavalent Chromium (Stainless Steel), Zinc Oxide (Galvanized Steel), Manganese, Aluminum, Nickel, Iron Oxide, Copper, Cadmium, Lead and Beryllium fumes.

Safety and comfort were Miller’s highest priorities when designing the Supplied Air Respirator (SAR) system. The result is an all-day apparatus for welding in the toughest industrial situations that keeps the operator cool and comfortable, prevents dangerous fumes from being inhaled, and ensures safe levels of carbon monoxide (CO).

SAR System Components

All SAR systems include the T94i-R Helmet, C50 Air Regulator, Belt Assembly, Flowmeter, Breathing Tube with Flame-Resistant Cover and Jobsite Tool Bag. Beyond these components, customers may choose from systems without a hose, with a 25-foot straight air hose, with a 100-foot straight air hose, with a 25-foot coiled air hose, or with a 100-foot coiled air hose. All hoses have a 360° swivel connection.

SAR Comfort & Safety Features

Helmet Comfort & Safety Features

BreatheAir Filtration System

The SAR System works with the BreatheAir Filtration System which not only filters air for the SAR System but provides further safety features and is integral to ensuring compliance and safety.

As the system continuously monitors CO levels in the breathing air, it filters the air in a three-stage process.

The BreatheAir Filtration System is available as a stationary panel or portable box system for up to two or up to four operators with CO monitors set to either 10 ppm (USA) or 5 ppm (Canada).