Increase Productivity with Hypertherm's FlushCut Consumables

Mar 11th 2021

Want to save time and materials by making close cuts with your plasma cutter? It’s as easy as adding a Hypertherm FlushCut nozzle to your Duramax torch.

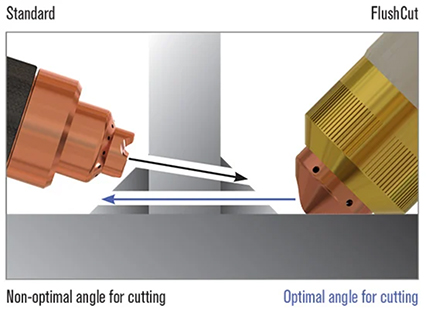

A recent innovation from Hypertherm, the FlushCut is a side-opening nozzle that forces the plasma arc in a 45-degree angle. As the flattened bottom of the nozzle shield sits on the workpiece, the plasma is forced out the side opening giving a close, parallel cut in a single pass.

How close a cut? The FlushCut nozzle leaves less than 5mm (3/16”) of material on the workpiece, reducing grinding and secondary repair operations. Additionally, with a flat bottom, lugs and attachments are more likely to be reused.

FlushCut consumables also make cutting weld access holes in I-beams easy, and will quickly remove bolts or other parts from metal plate.

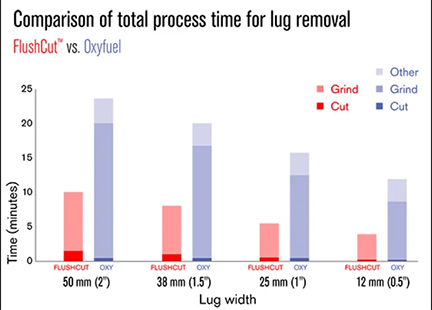

In a recent lab test comparing FlushCut to Oxyfuel, FlushCut was found to take less than half the time to remove lugs of various sizes.

FlushCut offers many benefits to increasing productivity:

- Heat affected zone (HAZ) associated with flush cutting is approximately ten times less than oxyfuel allowing a closer cut to the base material.

- Less overall pre-processing time than oxyfuel (e.g. no gas setting, purging or preheating).

- Remove lugs and attachments in a single pass compared to carbon arc gouging which requires multiple passes and additional time.

FlushCut consumables are available individually or as a kit for specific Powermax systems. Kits include a nozzle with shield, retaining ring, electrode, swirl ring and retaining cap.

FlushCut consumables can be used in both mechanized and handheld applications on the following Powermax torches and systems:

| System | Recommended amperage | Torch series |

| Powermax125® | 125 A | Duramax® Hyamp™ |

| Powermax105® | 105 A | Duramax® |

| Powermax85® | 45 A | Duramax® |

| Powermax65® | 45 A | Duramax® |

| Powermax45® XP | 45 A | Duramax® |

Note: FlushCut consumables are not compatible with Duramax® retrofit torches.