Walter Invents Long-Lasting E-Weld Pre-Coated MIG Nozzles

Mar 4th 2022

Tired of replacing or scraping out spatter clogged nozzles? Walter Surface Technologies has a new line of pre-coated E-Weld MIG nozzles that prevent spatter build up and last five times longer than untreated nozzles.

In fact, Water’s new E-WELD PRE-COATED NOZZLES™ are the only pre-coated MIG nozzles available anywhere.

"It took over 2 years of research and multiple failures to refine this unique ceramic solution and create an application process that offers exceptional durability to our welding nozzles. We are proud to bring to the market a product that respects the spirit of Walter Surface Technologies by helping our customers to work better and safer," says Philip Laforest, R&D Product Manager.

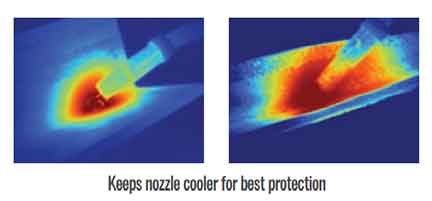

The formation of spatter is a time-consuming challenge frequently faced by welders and automated robotic welding. The new E-WELD PRE-COATED NOZZLES™ are made of high-quality copper with a unique ceramic coating on both the interior and exterior surface that prevents spatter from adhering to the nozzle. This prevents nozzle obstruction, allowing shielding gas to flow freely for higher quality welds. The ceramic material also provides long-lasting protection against heat damage.

Prior to the release of these pre-coated nozzles, the only prevention solution for spatter build up was aerosol sprays and gels but they are time consuming. They must be reapplied throughout the welding process, the torch has to cool down before reapplying aerosol solutions, and the solution must be dry before resuming welding. Furthermore, most aerosols are solvent based and flammable. The new E-WELD PRE-COATED NOZZLES™ are safe for all welding applications.

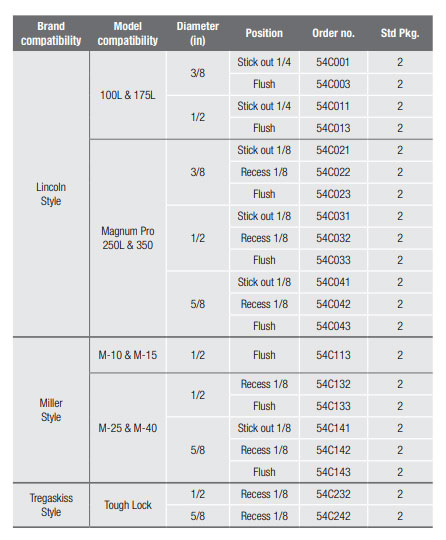

Without any modification or adaptors, the new E-WELD PRE-COATED NOZZLES™ are available in 1/2 inch, 3/8 inch and 5/8 inch, and models compatible with Miller®, Lincoln® and Tregaskiss® welding equipment.

Walter Surface Technologies has been a leader in surface treatment technologies for more than 60 years, and has been providing high productivity abrasives, power tools, tooling, chemical solutions and environmental solutions for the metal working industry. Founded in 1952, Walter Surface Technologies is now established in 7 countries in North America, South America and Europe.