Stop Leaks with Fluoramics' LOX-8 and Formula-8 TPFE Thread Sealants

Jan 21st 2022

Leaks can easily erupt when working with high pressure, high temperature and oxygen, but Fluoramics has developed revolutionary sealants that stop leaks longer on equipment used in welding and fabricating.

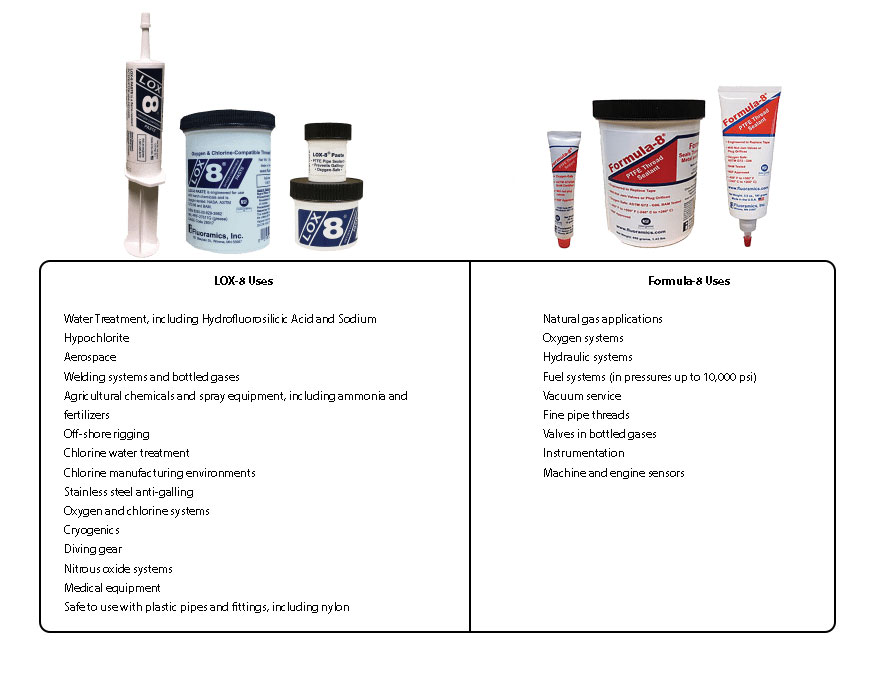

Among its most popular products, LOX-8 and Formula-8 are PTFE (Polytetrafluoroethylene) thread sealants with remarkable properties.

Both have been tested and certified for use with gaseous and liquid oxygen by NASA (ASTM G72-86) and also by BAM (German Federal Institute for Materials Testing), can withstand extreme temperatures and pressure, are food safe, and are made in the U.S.A.

The paste LOX-8 is a proven sealant where oxygen, harsh chemicals or powerful oxidizers are used. It is stable up to 500°F and cryogenic deep freeze temperatures.

Formula-8 uses PTFE in a shear-sensitive thixotropic paste to seal threaded joints with PTFE strings when torqued. Thixotropic means becoming less viscous when subjected to an applied stress, so the seals are formed over the entire thread length, even the fine threads used in instrumentation systems. Formula-8 won’t deteriorate from ‐400°F to +500°F and is stable in pressures up to 10,000 psi and in vacuums 10‐3 torr.

Fluoramics customer J. C. said LOX-8 solved all his leak issues: “…I had leaks on my chemical feed lines on my Sodium Hypochlorite system. After the LOX-8 resolved those issues, I applied it to my Sodium Hydroxide system and then my Aluminum Sulfate system. I no longer have leaks. I wish I knew about this product years ago. Highly recommend this product!”

For customer D. T., LOX-8 solved a long-term leaky fitting: “…we tried multiple thread sealants that would just break down and start to leak…the LOX-8 has kept the Hypochlorite in our pipes and off our floors! Due to its success, we have started using it on other chemical pipe fittings throughout our facility.”

Are you new to gas-quality PTFE paste? Fluoramics offers these helpful tips for working with LOX-8 and Formula-8:

Troubleshooting

One of the safest ways to check for leaks is to apply soapy water to the assembly and slowly pressurize. If you see soap bubbles, you know you have a leak. Examine where the bubbles are coming from. Look carefully at the piping and joints for cracks. Common problem areas are the seams, valve stems, main connections, hose connections and bleed screws, when applicable. If the bubbles appear to come from the joint, take the joint apart to make sure there is enough sealant in the threads to form a perfect seal.

Proper Application of a Thread Sealant without Over Torqueing

To apply a thread sealant, start about 2 threads back from the front end of fitting to prevent paste from protruding into your product stream. Apply enough paste to fill the threads. Assemble and hand tighten with perhaps another quarter turn and leave it there. Be careful to not over torque; it is very easy to over torque and crack or strip the threads on plastic, PVC or cast-iron fittings, causing the assembly to leak. Watch for and replace all cracked plastic nuts. This is not a sealant event but is caused by over torque.

Dissimilar Connections

When working with dissimilar connections, watch for different screw threads. One example is using National Pipe Tapered (NPT) fittings with National Gas Taper (NGT) fittings. The NGT is a longer screw thread than NPT. The two pieces will assemble together, but the NGT will typically have 3 more threads in the fitting area. If you mount an NPT to an NGT, you will have leaks. Also, when using dissimilar types of plastics, you may run into the threads not properly aligning. The first few threads may line up but as you continue to tighten, the threads may not align. This will cause gaps and leaks. The thread sealant will provide bulk fill and help with the leaks but the problem rests with the dissimilar types of plastics and not with the quality of the sealant.

Fluoramicshas been engineering high-quality lubricants, greases, rust stoppers and oxygen/chlorine-compatible thread sealants since 1967. Weldfabulous is proud to be a distributor of Fluoramics’ popular sealant, lubricant and rust inhibitor products. Both companies are located in Winona, Minnesota.