Lincoln Electric Activ8x Wire Feeder Offers Compact Lightweight Portability

Jan 17th 2022

Lincoln Electric is back with more innovations that show its commitment to continually improving its products and processes to make work faster, less expensive, and safer for operators.

The Lincoln Electric Activ8x Wire Feeder combines new technology with strong yet lightweight materials to create the industry’s lightest portable, semiautomatic wire feeder.

“Field welding applications can be demanding, as it requires a wire feeder solution that provides portability, reliability, and a variety of welding process for different applications and materials.” states David Jordan, Global Industry Segment Director – Process Industries. “Thanks to the new Activ8x, we now have an ideal solution to effectively meet these requirements; offering a rugged, lightweight wire feeder packed with advanced technology typically used in shop environments that you can now take out to the field or in remote locations.”

The key to the success of Activ8x is Lincoln Electric’s CrossLinc Technology. CrossLinc allows the power source to be controlled remotely so there’s no need for control cables. Communicating through the weld leads means no more lugging heavy control cables around the job site, and fewer, faster connections.

Because an operator can be up to 200 feet away from the power source, CrossLinc Technology works with Lincoln Electric’s True Voltage Technology to ensure the correct voltage is received.

Long cables and multiple connections can create a difference in voltage (voltage drop) between the power source and the weld and may result in a cold weld. But communication between CrossLinc and True Voltage technologies and Activ8x automatically compensates for voltage drops to ensure the correct voltage is available at the arc.

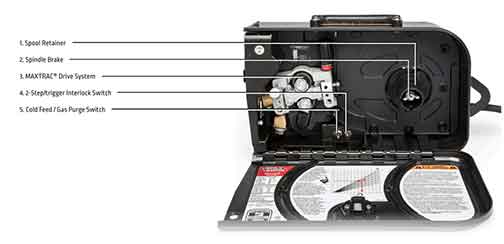

Outside, the Activ8x features an impact-resistant, flame-retardant case ready to endure the toughest conditions. Inside, the mechanics are well-protected and designed for accuracy and reliability. The Maxtrac® Wire Drive System is a heavy-duty cast aluminum wire drive system that provides reliable feeding and durability, and the system’s tachometer feedback delivers accurate wire feed speed.

With all its innovations the Activ8x is popular with the construction, offshore and shipbuilding industries. At 11.8 in x 7.4 in x 18.7 in (298 mm x 188 mm x 475 mm) it is compact enough to fit through manways and at 27.5 pounds (12.474 kg) it is light enough to carry around any job site.

Activ8x model LIK3519-1 has an electrode lead with a Tweco® style connector and Activ8x CE model LIK3519-2 has a Twist Mate/Dinse connector as standard. Model K3564-1 includes the Activ8x Wire Feeder and Magnum® PRO Curve™ 300 Welding Gun (LIK2951-2-10-116).